Keox Technologies, Inc. and Innomiles International Co., Ltd. have announced a strategic partnership offering industrial machine vision solutions for customers in Asia and North America. Based on the cooperation, Keox Technologies will develop machine vision and other non-contact inspection solutions utilizing resources from Innomiles’ machine vision software and hardware, in addition to developing state-of-the-art customized inspection solution for end users. The goal of this strategic partnership is in strengthening and expansion of activities in both Asia and North America and building up the following business operation portfolio: Distribution of Innomiles software licenses and hardware components Application consulting Maintenance,

Read More

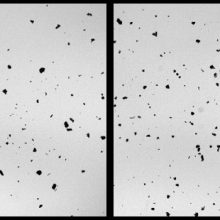

Measuring Particle Sizes and Process Control – Controlling Size Process using Bhattacharyya Distance

Keox Technologies occasionally encounters a request in measuring particle size distribution. That is, when making measurements on powders, minerals, rice, beans, grains, and even contaminant particles, a specific dimension number isn’t given but rather a distribution (or terminology used more in the Imaging world, a histogram). The challenging part is how to determine if one distribution is similar to the control distribution or if it’s significantly different? How does Process Engineering determine if incoming raw materials are within specification or that the fabrication process is out-of-control? There are many different metrics of comparing – ranging from simple to

Read More

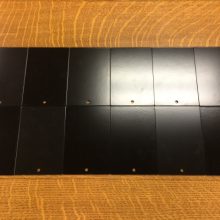

There’s a Black and a Darker Black – Controlling Color

Keox Technologies was given an application by a client where they needed to differentiate colors of powder coated metal. The challenge is that some powder being Electrically Spray Deposited (ESD) were very similar in color such that the human eye cannot easily distinguish the coating result. Additionally, natural process variability of the powder coating process, such as varying film thicknesses, baking temperature variation, and even contamination of the chamber, also affected the final color result. With the subtle wrong color used, it caused product variations and gave the perception of lesser quality control, especially when parts are placed next to

Read More