Keox Technologies, Inc. and Innomiles International Co., Ltd. have announced a strategic partnership offering industrial machine vision solutions for customers in Asia and North America. Based on the cooperation, Keox Technologies will develop machine vision and other non-contact inspection solutions utilizing resources from Innomiles’ machine vision software and hardware, in addition to developing state-of-the-art customized inspection solution for end users. The goal of this strategic partnership is in strengthening and expansion of activities in both Asia and North America and building up the following business operation portfolio: Distribution of Innomiles software licenses and hardware components Application consulting Maintenance,

Read More

Why We Need Bold, Long-Term Innovation Strategies

Smart Manufacturing Magazine posted an article that Keox Technologies strongly believe in. We have been advocating similar concepts with industry colleagues, partners, and customers. This article articulates very well the less obvious, yet very significant, facts of how manufacturing innovation is crucial in driving the market and economy. I have been taught by my mentor that whatever location manufacturing go, all other industries follow even if they are related to factory production or not. This article confirms that idea. Manufacturing and Innovation are highly linked together – both sequentially and as a feedback cycle. Manufacturing implements the discoveries

Read More

This is NOT an example of Lockout-Tagout (LOTO)

I’d have a word with the Safety Officer if I see this onsite!

Read More

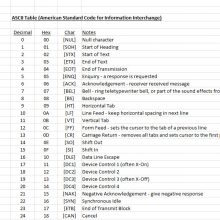

ASCII Table with Descriptions – Machine Vision Software Code Reference

ASCII, acronym for “American Standard Code for Information Interchange”, was developed in the 1960’s but is still in important use today. (No matter what people say about RS-232, it’s still the appropriate protocol to use sometimes AND it’s still very reliable!) More often than not, we need access to the ASCII tables when we’re coding our applications in C#. Therefore, the following is a handy reference that we’d like to share with fellow engineers. The standard table has 128 characters, using 7-bits with the 8th bit as a parity check. The term “Extended ASCII Code” is somewhat unclear,

Read More

Equipment and Project Safety – Machine Vision Design and Installation

“Safety First!” – as cliché as it sounds and sometimes even said in humor, it is a very important statement. It is a deep conviction by the employees, managers, and owners of Keox Technologies, that NOBODY will get hurt or injured – employees, customers, vendors and anyone else. Although it’s a 24-hour constant task, one regular activity that we really apply our safety conviction to is during our system installs.

Read More

Measuring Particle Sizes and Process Control – Controlling Size Process using Bhattacharyya Distance

Keox Technologies occasionally encounters a request in measuring particle size distribution. That is, when making measurements on powders, minerals, rice, beans, grains, and even contaminant particles, a specific dimension number isn’t given but rather a distribution (or terminology used more in the Imaging world, a histogram). The challenging part is how to determine if one distribution is similar to the control distribution or if it’s significantly different? How does Process Engineering determine if incoming raw materials are within specification or that the fabrication process is out-of-control? There are many different metrics of comparing – ranging from simple to

Read More

The Vision Show 2018 Boston – Top 3 Takeaways from This Year’s Show

Every other year the Machine Vision industry looks forward to one of the most important trade shows for us in the industry – The Vision Show. This year, The Vision Show 2018 seems to be a little bigger than in the past, with 150+ exhibitors in Boston. As with most industry and tradeshows, The Vision Show 2018 highlighted trends in the industry with conferences and speakers. The latest trends in the industry seems to be in Embedded Vision, Industrial Internet of Things (IIoT), Collaborative Robots (Cobots), to just name a few. Instead of focusing on the usual highlights of the

Read More

Using Machine Vision to Improve Six Sigma – Rigorous Use of DMAIC Can Really Improve Your Product Quality

Applying the Six Sigma process can improve manufacturing performance and improve quality. Six Sigma is a set of statistical tools and data-driven process used for process improvement – whether it is for manufacturing, finance, customer service, or any business process that can benefit from process improvement. Of course for Keox Technologies, we work mainly in the context of manufacturing and improving our customers’ quality and process control. There are two main methodologies of Six Sigma – DMAIC and DMADV (for “Define, Measure, Analyze, Improve, and Control“ and “Define, Measure, Analyze, Design, and Verify“, respectively). Keox Technologies follows a variant that

Read More

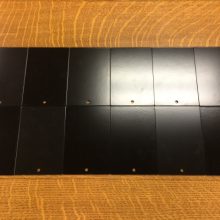

There’s a Black and a Darker Black – Controlling Color

Keox Technologies was given an application by a client where they needed to differentiate colors of powder coated metal. The challenge is that some powder being Electrically Spray Deposited (ESD) were very similar in color such that the human eye cannot easily distinguish the coating result. Additionally, natural process variability of the powder coating process, such as varying film thicknesses, baking temperature variation, and even contamination of the chamber, also affected the final color result. With the subtle wrong color used, it caused product variations and gave the perception of lesser quality control, especially when parts are placed next to

Read More

Jack of All Trades, Master of Some – 5 Most Important Skills to Look for in a Machine Vision Engineer

There’s no doubt about it – the Machine Vision Industry is poised to grow. It’s valued at 9.10 billion USD in 2016 and $19.22 billion by 2025. It’s clear that demand for Machine Vision Engineers is growing proportionally in order to handle this growth.

Read More